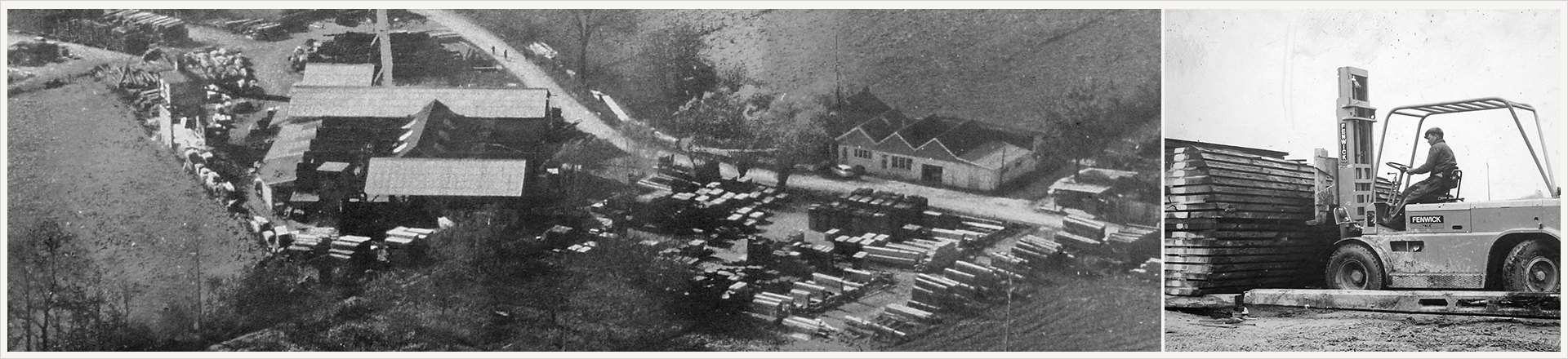

Overview of The TARTERET Philippe SA sawmill

The story of The TARTERET Sawmill begins in 1954 when Philippe TARTERET, aged of 22, arrives in Estissac in Aube (150 km south-east of Paris).

1954-1965 :

Development of the sawing equipment.

1967 :

Philippe TARTERET launches the artificial wood drying operation.

He then will regularly increase the sawmill capacity by adding a pre-drying room and a vacuum drying room. In order to grow his business, he sets up efficient technical installations to ensure production quality.

1985 :

With the installation of a double-way-cut-saw, the sawmill significantly increased its sawn timber production. A modern crosscutting logs station added to a debarker is then installed.

1993 :

Creation of a sawn-cut-to-size workshop, allowing us to offer all kind of dried wood timber products. Installation of a multiple-blade ripping saw, in order to define precision cuts, according to customers’ specifications.

1998 :

Set-up of a trimming activity, in order to optimize production of strips and square-edged.

1999 :

The TARTERET Sawmill is the first French sawmill specialized in oak and hardwoods to have obtained the ISO 9002 and then ISO 9001 certifications.

2000 :

Installation of a second multiple-blade ripping saw and automatic stacker.

2001 :

Installation of a horizontal bandsaw allowing to saw big and long beams (up to 15 meters)

2003 :

The sawmill obtains the PEFC Certification for logs, sawn timber in oak and other hardwoods.

The TARTERET Sawmill quickly supports sustainable development initiatives.

2008 :

Construction of a customer hall for boules control and measure with a radio-controlled vacuum lifter.

2010-2011 :

Installation of an air conditioning system in three dried wood warehouses.

2013 :

The sawmill obtains the ICPE authorization (environmental protection zoning, a three steps French governmental process to prevent and reduce certain environmental risks).

2015 :

Installation of a new stacking and sorting area in the sawmill with an automatic vacuum lifter.